Meet the roughness required for dry film pretreatment and resistance welding pretreatment. The micro corrosion amount of dry film pretreatment can be as low as 0.4um, and the roughness

The product does not contain ammonia nitrogen, the wastewater treatment is simple, and meets the requirements of environmental protection

The copper content can be up to 60g / L, which can greatly reduce the consumption, save the cost, and reduce the cost of wastewater discharge and treatment

Uniform color and no color difference defects

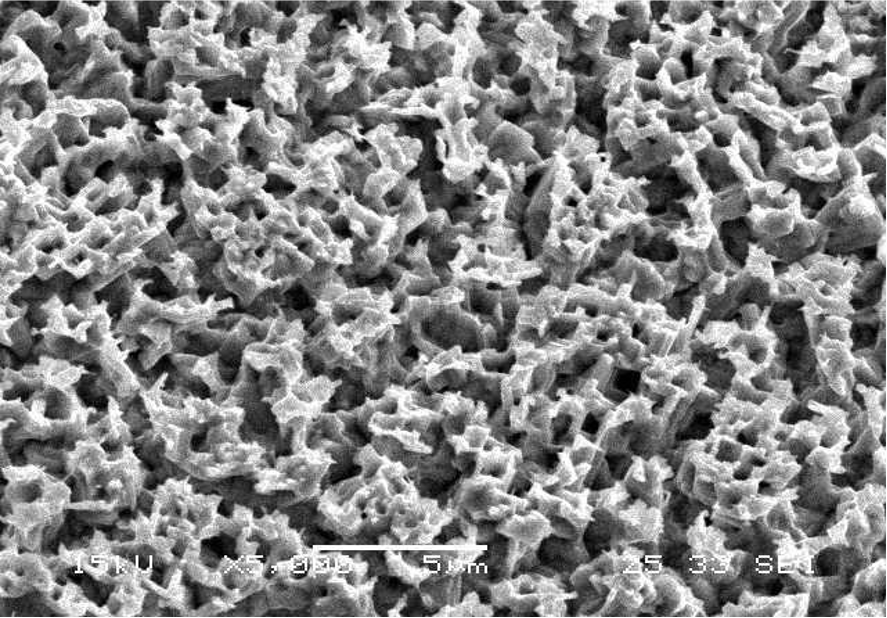

Morphology comparison

Different Comparison of morphology of copper 3510 electroplating with micro etching amount

Rz3.46um Ra:0.25um S/A:2.73 Rz:2.89um Ra:0.39um S/A:0.65 Rz:3.93um Ra:0.52um S/a:3.18

(Micro erosion 0.51um) (Micro erosion 0.71um) (Micro erosion 1.14um)

With the increase of micro etching amount, the roughness and specific surface area of electroplated copper surface gradually increase. The appropriate micro etching amount can be selected according to the demand

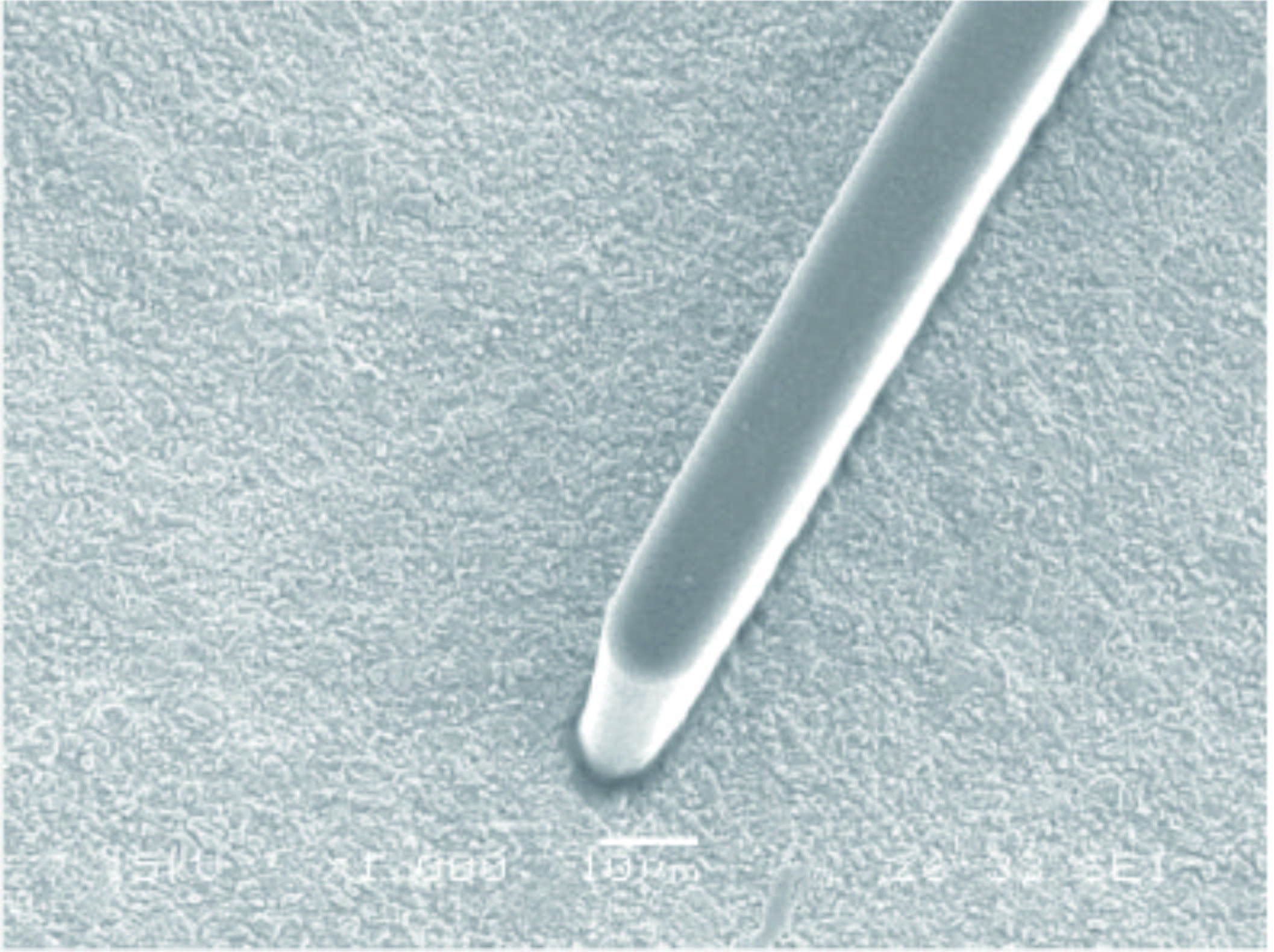

Dry film adhesion

After micro etching 0.5um with ultra roughening solution 3510 on the copper surface, the dry film adhesion can reach 10um, and the dry film is rd1225(Hitachi)

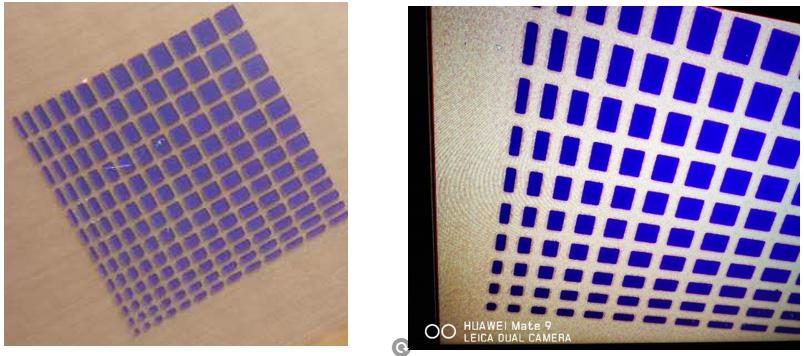

On the super roughened substrate, make pads of different sizes. After development, pull them with 3M tape. The minimum 3 * 3mil pad is not allowed to fall off.

Shangrong ultra roughened substrate for such adhesion test. The above figure is the sample diagram after Shangrong substrate test. There are no pad falling for 100 areas.

The super roughened substrate of a Japanese brand did not fall in 100 areas.

For other domestic suppliers, the drop ratio of minimum pad is high than 95%.

SCAN