Performance Characteristics

It can fill blind holes with different aperture and depth width ratio, and can fill a variety of holes (blind holes and through holes)

The hole filling morphology is excellent, the surface copper thickness is thin and concave size is small

Short electroplating time and high production efficiency

The plating solution and additive system are stable and durable with high utilization rate

It can be applied to a variety of substrate materials (HDI, flexible board, silicon substrate)

Treatment Effect

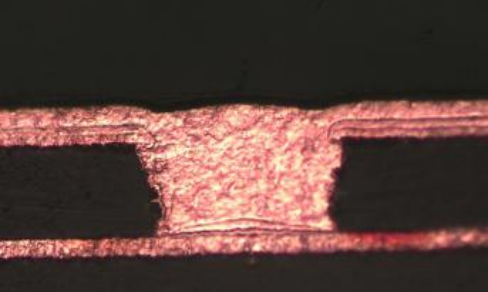

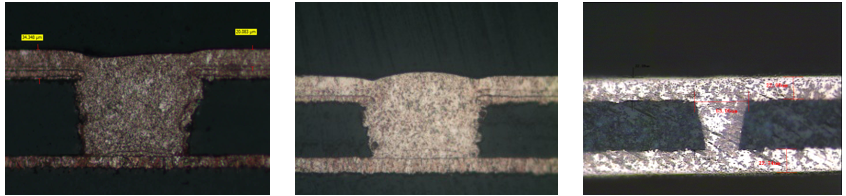

Blind hole filling effect - HDI

Electroplating parameters and performance (taking diameter of 100um as an example)

| Current density | Electroplating time | Light agent ratio | Surface copper thickness | The depth of the pit |

| 2.0ASD | 50min | S:A:L=10:1:15 | <16um | 10um |

Diameter of 150 um Diameter of 100 um Diameter of 50 um

Line for filling uniformity of 150um diameter blind hole

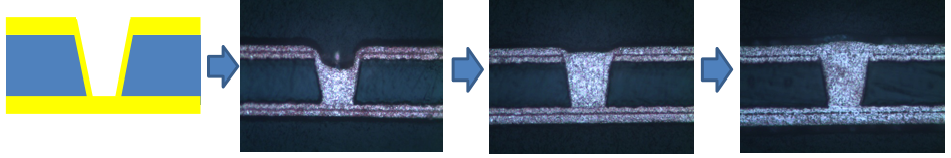

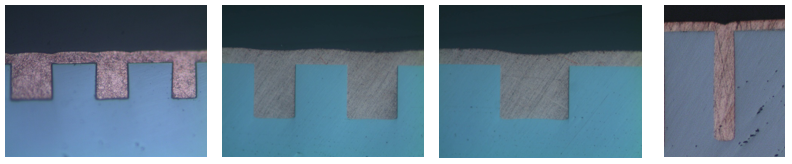

Blind hole filling results - soft board

Electroplating parameters and performance (taking diameter of 50um as an example)

| Current density | Electroplating time | Light agent ratio | Surface copper thickness | The depth of the pit |

| 1.7ASD | 35min | S:A:L=15:0.75:15 | <10um | 2-4um |

Hole prototype Electroplating 25 min Electroplating 35 min Electroplating 45 min

Hole prototype Electroplating 25 min Electroplating 35 min Electroplating 45 min

Plating light agent can achieve 20-150um diameter blind hole filling

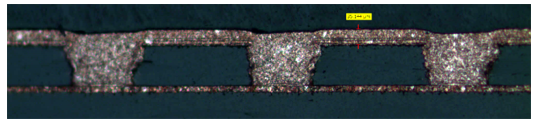

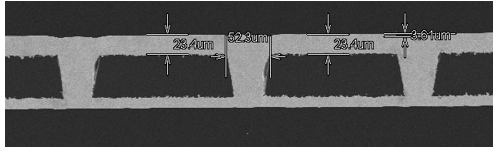

Blind hole filling results - silicon substrate

Electroplating parameters and performance

| Size | Current density | Electroplating time | Light agent ratio | Surface copper thickness | The depth of the pit |

| Low deep than wide | 2.0ASD | 45min | S:A:L=10:1:5 | <15um | <5um |

| High deep than wide | 0.4ASD | 180min | S:A:L=10:0.75:15 | <15um | <5um |

Electroplating light agent can achieve 10-60um diameter silicon based blind hole filling

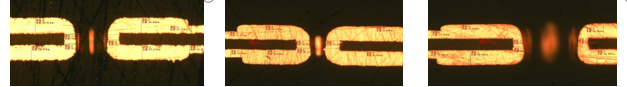

Plating results of soft plate through hole

| The aperture | 100um | 100um | 150um |

| Current density | 1.1ASD | 1.3ASD | 1.5ASD |

| Time | 50min | 40min | 36min |

| Thickness of copper on pad | 28.6um | 29.7um | 29.1um |

| At the end of the thickness of the copper | 15.4um | 16.3um | 15.9um |

| Copper thickness | 22.1um | 23.8um | 21.0um |

| Average TP | 1.68 | 1.77 | 1.59 |

Soft board through hole filling results

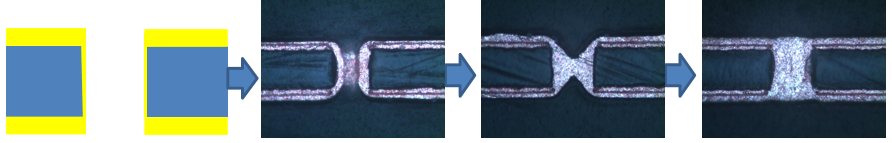

Electroplating parameters and performance

| Current density | Electroplating time | Light agent ratio | Surface copper thickness | The depth of the pit |

| 1.7ASD | 35min | S:A:L=15:0.75:15 | <10um | 2-4um |

Hole prototype Electroplating 15 min Electroplating 25 min Electroplating 35 min

SCAN